FLOAT

What if kitchen utensils could be easily elevated above the work surface within arms reach freeing up precious counter space?

Counter space, especially in apartments and other small dwellings, is critical to being able to successfully operate in the kitchen. Float allows for all of your favorite utensils to be stored above the work surface freeing up valuable counter space and helping you find what you need quickly and easily.

Float is currently being licensed and produced by Umbra.

Throughout the project I worked closely with an industry mentor in Walter Herbst who helped guide me through the process, challenge my ideas, and bring the concept into reality.

Final manufacturing ready model of float - Image courtesy of Umbra - umbra.com

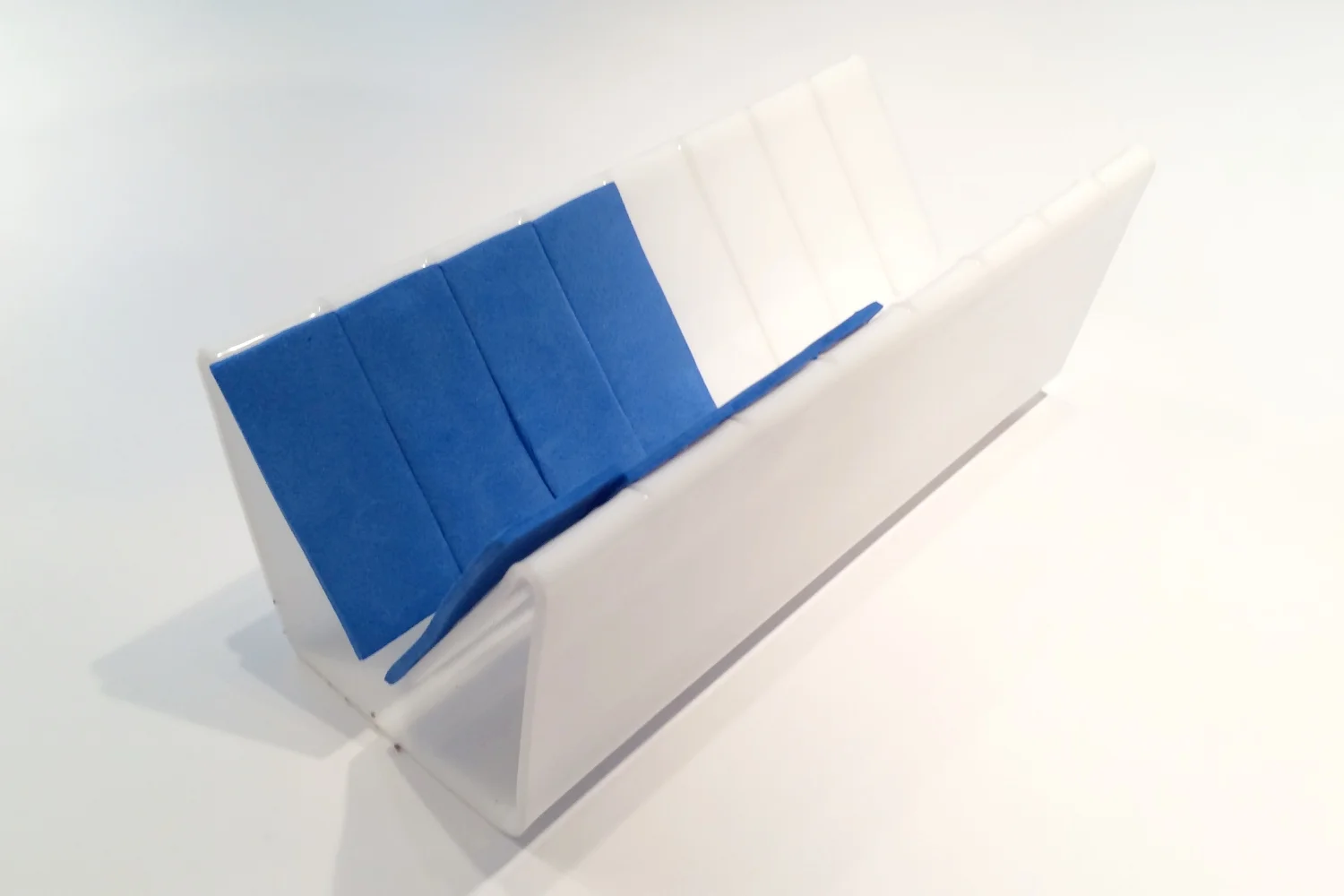

Final prototype of Float

What do desktops and counters have in common?

Float was designed as my Masters Thesis Project while enrolled in the MS EDI program at Northwestern University. I worked closely with my mentor, Walter Herbst, to design a product that could showcase what I had learned in my time in EDI. I began by exploring desk space and observed something seemingly obvious; most horizontal work surfaces collect clutter. People also tend to keep tools that they use frequently close at hand.

After working on desk space, I eventually transitioned the project to the kitchen. Kitchens are spaces that oftentimes have small work surfaces, but require space to cook effectively. I noticed that there is frequently underutilized space beneath the upper cabinets and began generating concepts that might make more effective use of that space.

The surgical tubing prototype that eventually led to Float

From beer bottles and Bisquick boxes to slotted spoons, and spatulas.

There was something so pleasant and delightful about the experience of being able to seemingly suspend objects in midair. Although it was great to be able to hang things in this space, the method of doing so did not work particularly well. I did however learn that a small amount of pressure and friction work well to suspend rather heavy objects.

A survey of different handle types and sizes

Skinny handles don't hang with their fat neighbors.

One of the main challenges was being able to accommodate a wide range of handle shapes and sizes. Much like desk spaces, people tend to keep the utensils they most frequently use out of the drawers and within arms reach. These tools also often happen to be mismatched sets gathered over the years.

The first folded plastic prototype with individual “fingers” allowing different sized handles to live peacefully together

Plastic + Foam + ‘Fingers’ = Grip

I eventually found an elegant way to grip utensils of all shapes and sizes. Drawing on experiences in the vacuum-formed plastics industry, I heated a laser cut sheet of acrylic and bent it into the shape of an ‘M’. I added strips of craft foam for additional gripping power and long story short, it worked.

The final prototype with a packaging concept in a foam core kitchen

From folded plastic to Float.

Once the folded acrylic prototype proved successful, I needed a way to construct something that looked like a real product. I developed a three-part molding tool, a more complex laser-cut part, and a brand to bring the concept to life.

Finally, I imagined a wrap-around image packaging concept and displayed all of my work in a foam-core kitchen. To display how the product worked, I produced a 30-second stop-motion animation set to the tune of Float On by Modest Mouse.